Diamond Sharpening Stone Abrasion Rates

Diamond Sharpening Stone Abrasion Rates

It is a common assumption that a coarser diamond stone will remove metal more quickly than a finer, higher grit stone however; this is often not the case.

There are several factors that affect how quickly a given grit will remove metal. These factors include the pressure applied, the shape of the diamond particles, the hardness of the steel being sharpened, and the metallurgic composition of the steel.

The speed that a 300, 600 or 1200 girt stone removes metal depends a lot on the steel you are sharpening. On very soft steel the 300 grit diamond stone might remove metal more quickly but on harder steels (like the steel on most knives and tools) the 600 will often remove metal faster. I'll try to explain.

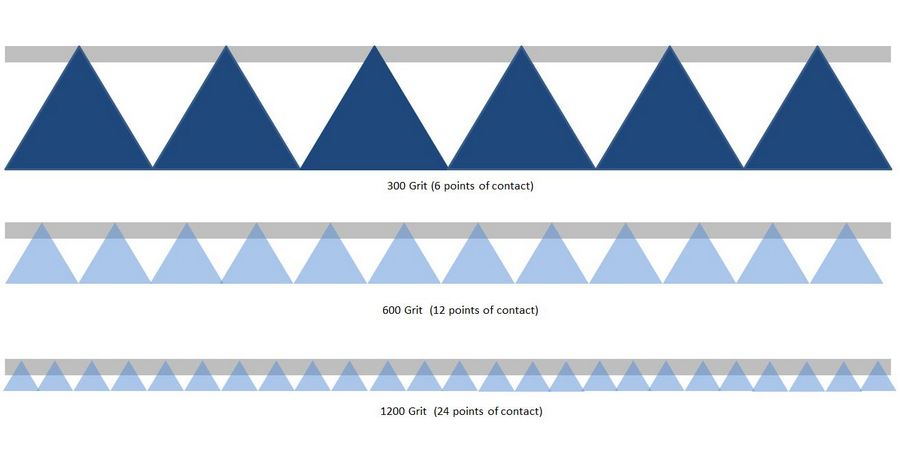

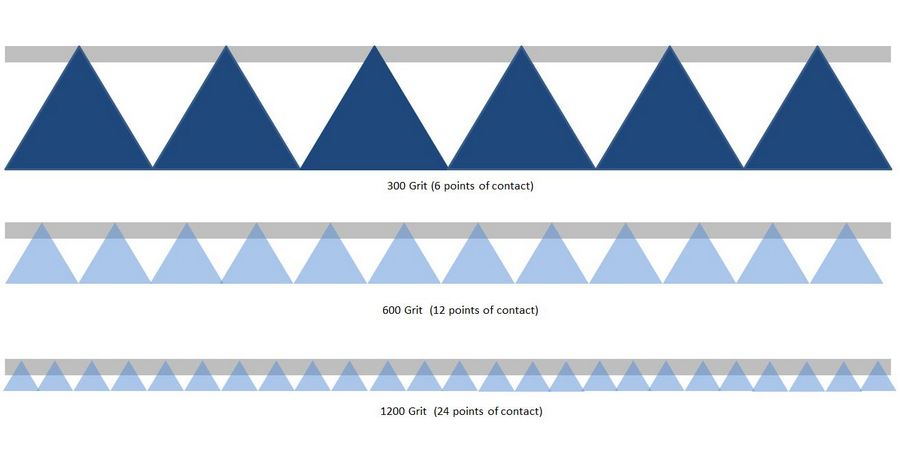

The particle size on a 300 grit stone is twice as large as the particle size on the 600 grit stone. Therefore, there are twice as many diamonds per square inch on the 600 grit stone as the 300 grit stone. If you are using a 300 grit stone you only have half the surface area actually touching the blade you are sharpening. Let's assume for this example that the diamonds are shaped like a pyramid. Although the diamonds on the 300 grit are larger, you only have half as many points touching the blade. Because the steels are hard there isn't much penetration of the points. A 600 grit stone will usually cut faster than a 300 unless the steel is very soft (like on a hatchet) or you can exert a good amount of pressure down onto the stone (like when using a jig, working the tips of knives or sharpening small carving tools). On most tool steel the 600 grit is going to cut faster.

However, if you are sharpening a softer steel like on an axe or machete, the points of the 300 grit stone will likely penetrate deep enough to remove metal more quickly. The 300 grit is best for softer steels or situations when you can put a lot of pressure onto the blade (like in a jig). If I have a really abused edge to sharpen, I do use my 300 for harder steels but the main reason I do is to save my 600 from abuse. I don't expect it to cut very fast. I will typically use a Razor Edge Angle Guide for knives or a jig for planes and chisels which allows me to exert much more pressure down onto the stone.

However, if you are sharpening a softer steel like on an axe or machete, the points of the 300 grit stone will likely penetrate deep enough to remove metal more quickly. The 300 grit is best for softer steels or situations when you can put a lot of pressure onto the blade (like in a jig). If I have a really abused edge to sharpen, I do use my 300 for harder steels but the main reason I do is to save my 600 from abuse. I don't expect it to cut very fast. I will typically use a Razor Edge Angle Guide for knives or a jig for planes and chisels which allows me to exert much more pressure down onto the stone.

There is a great article here Abrasion Rate vs Grit that goes into even more detail as to why a 300 grit stone removes metal more slowly than a higher grit sharpening stone. In their experiments the 1200 girt diamond stone removed metal approximately 10 times faster than the 300 grit stone. In fact the Shapton 1600 grit glass stone was proven to remove metal at almost the same rate as a 300 grit diamond stone. At higher pressure the coarser stones do begin to remove metal faster than the finer grit stones but there still isn't much of an advantage.

The explanation for this is simple: coarse stones only remove metal faster if sufficient pressure can be applied to the stone to penetrate the steel deep enough to remove more metal per stroke or the steel being sharpened is fairly soft. You must be able to supply sufficient pressure onto the stone to remove metal; otherwise the steel will simply slide over the stone.

Summary

A higher grit diamond stone will remove metal more quickly unless sufficient pressure can be applied. The 300 grit stone is best used to work small surface areas like narrow chisels and knife tips where greater pressure per square inch can be applied. For larger surface areas or to flatten the back of chisels and planes, it is best to use a 600 or even 1200 grit diamond sharpening stone.

We hope you found this article helpful. If you have questions or comments please Contact Us.

To read our Use & Care of Diamond Sharpening Stones article click here - Use and Care of Diamond Sharpening Stones

To read more articles please click here - Articles

It is a common assumption that a coarser diamond stone will remove metal more quickly than a finer, higher grit stone however; this is often not the case.

There are several factors that affect how quickly a given grit will remove metal. These factors include the pressure applied, the shape of the diamond particles, the hardness of the steel being sharpened, and the metallurgic composition of the steel.

The speed that a 300, 600 or 1200 girt stone removes metal depends a lot on the steel you are sharpening. On very soft steel the 300 grit diamond stone might remove metal more quickly but on harder steels (like the steel on most knives and tools) the 600 will often remove metal faster. I'll try to explain.

The particle size on a 300 grit stone is twice as large as the particle size on the 600 grit stone. Therefore, there are twice as many diamonds per square inch on the 600 grit stone as the 300 grit stone. If you are using a 300 grit stone you only have half the surface area actually touching the blade you are sharpening. Let's assume for this example that the diamonds are shaped like a pyramid. Although the diamonds on the 300 grit are larger, you only have half as many points touching the blade. Because the steels are hard there isn't much penetration of the points. A 600 grit stone will usually cut faster than a 300 unless the steel is very soft (like on a hatchet) or you can exert a good amount of pressure down onto the stone (like when using a jig, working the tips of knives or sharpening small carving tools). On most tool steel the 600 grit is going to cut faster.

There is a great article here Abrasion Rate vs Grit that goes into even more detail as to why a 300 grit stone removes metal more slowly than a higher grit sharpening stone. In their experiments the 1200 girt diamond stone removed metal approximately 10 times faster than the 300 grit stone. In fact the Shapton 1600 grit glass stone was proven to remove metal at almost the same rate as a 300 grit diamond stone. At higher pressure the coarser stones do begin to remove metal faster than the finer grit stones but there still isn't much of an advantage.

The explanation for this is simple: coarse stones only remove metal faster if sufficient pressure can be applied to the stone to penetrate the steel deep enough to remove more metal per stroke or the steel being sharpened is fairly soft. You must be able to supply sufficient pressure onto the stone to remove metal; otherwise the steel will simply slide over the stone.

Summary

A higher grit diamond stone will remove metal more quickly unless sufficient pressure can be applied. The 300 grit stone is best used to work small surface areas like narrow chisels and knife tips where greater pressure per square inch can be applied. For larger surface areas or to flatten the back of chisels and planes, it is best to use a 600 or even 1200 grit diamond sharpening stone.

We hope you found this article helpful. If you have questions or comments please Contact Us.

To read our Use & Care of Diamond Sharpening Stones article click here - Use and Care of Diamond Sharpening Stones

To read more articles please click here - Articles