How to Test Sharpening Stone Flatness

Testing Sharpening Stone Flatness

Before we look at the different methods for testing sharpening stone flatness, let's review some terms that often cause confusion.

Stone Thickness: The distance between the top and bottom surfaces of a stone. This distance is most commonly measured by using precision micrometers. Before we look at the different methods for testing sharpening stone flatness, let's review some terms that often cause confusion.

Stone Parallelism: Parallelism is related to thickness. Parallelism is the difference between the thickest and thinnest points on a stone (example: if the thinnest measurement of a stone is .500" and the thickest measurement is .505", the stone is said to be parallel within 0.005").

Stone Flatness: Flatness is not related to thickness or parallelism. Stone flatness is measured relative to a reference surface such as a certified granite slab. Flatness is most commonly measured as a deviation from the reference surface.[1]

Measurements in thousandths of an inch: Sharpening stone flatness is typically measured in thousandths of an inch. This number may be shown as a decimal or a fraction. For example, you might see one thousandths of an inch shown as .001 or 1/1,000.

Tenths: In some discussions about flatness tolerances you might see someone involved in quality control testing use the term "tenths". When they use the term "a tenth" or "1/10th's" they are referring to one ten-thousandths of an inch not one-tenth of an inch.

Now, let's look at the four method for testing flatness.

4 Methods for Testing Sharpening Stone Flatness

Items Needed:

- Machinist Straight Edge

- Feeler Gauge

Instructions:

A good quality straight edge should be certified to within a minimum of 0.001" over the entire length and can be purchased for under $50.

Before beginning this test it is important to make sure the straight edge is perfectly clean, free of dust or other foreign debris and that there are no nicks, dents or other damage to the testing surface of the straight edge. We typically clean the testing edge with 1 micron lapping film and wipe it with a lint free cloth prior to beginning testing. Also, you should periodically test the straight edge for testing on a certified Granite Surface Plate.

Place a Machinist Straight Edge across the length or width of the stone, hold the center point of the straight edge with medium pressure. Test by inserting a feeler gauge of the desired thickness between the stone and the straight edge at as many points as desired.

You can also hold the stone and the straight edge up to a light source and check to see if you can see any light passing between the straight edge and the stone. This method will not give you a measurement but it is a quick way to see if the stone is flat.

This method is by far the easiest and quickest method to test a sharpening stone for flatness. It takes less than a minute to perform and provides very accurate results comparable with the more time consuming and expensive Dial Indicator Method. In addition, training someone to become proficient at obtaining accurate results with this method takes little time.

(IMPORTANT NOTE: A machinist's ruler or machinist square is NOT an acceptable instrument for measuring flatness. They are not designed to be flat and are not acceptable to test flatness or parallelism.)

Method 2: Dial Indicator Method:

Items Needed:

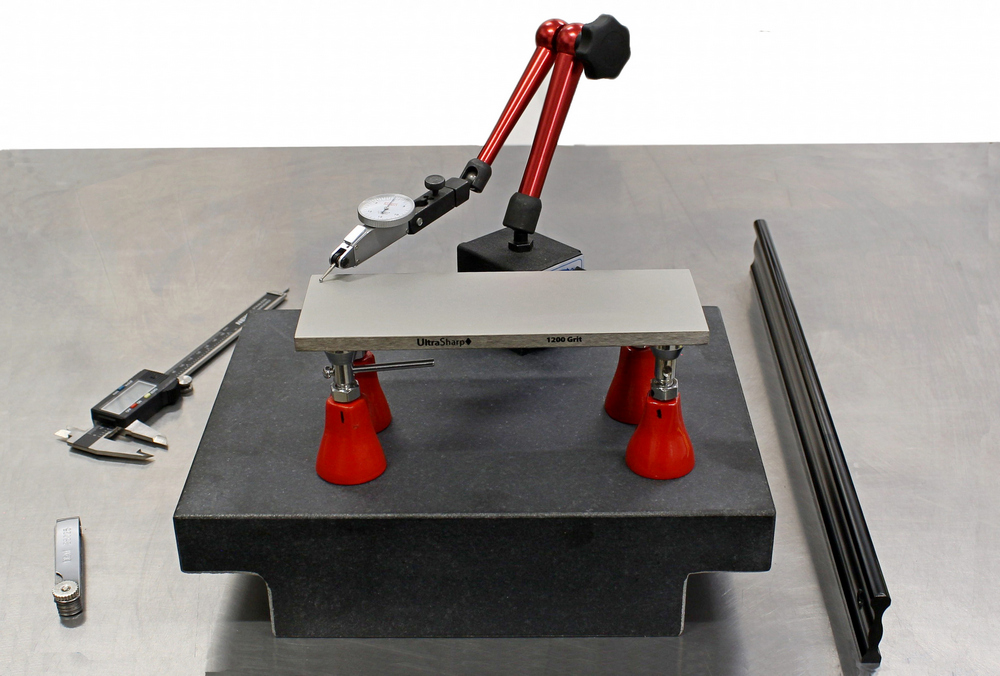

- Granite Reference Plate

- Dial Indicator on a stand

- Adjustable Jacks

Instructions:

1. Place the granite reference plate on a solid surface.

2. Place the three adjustable jacks on the reference plate.

3. Place your sharpening stone on the adjustable jacks making sure that the surface that requires flatness testing is facing up with the adjustable jacks at 3 points near the perimeter of the stone.

4. Place the dial indicator and stand on the reference plate. Adjust the jacks so that all points directly above the jacks read zero on the dial. This is a critical step and must be done with great care and accuracy or the results will be flawed.

5. Sweep the surface of the stone with the dial indicator and record the measurements. These measurements will be the variation from zero with the maximum variation being the flatness.

This method is considered the most accurate manual method by most machinists but it is also the most difficult to perform. This method requires time and patience to set-up. For measuring the flatness of a sharpening stone we have found that it produces very similar results to the Machinist Straight Edge Method above. Also, there is the matter of cost. This cost of buying the reference plate, jacks and indicator is around $400 (with an inexpensive gauge) and could easily exceed $1000 if one chooses to go with a higher quality gauge. Conversely, The tools required to perform the Machinist Straight Edge Method can be purchased for as little as $50.

Method 3: Granite Surface Plate Method:

Items Needed:

- Granite Surface Plate

- A Feeler Gauge

Instructions:

Lay the diamond side of the stone face down on the Granite Surface Plate. Test by inserting a feeler gauge of the desired thickness between the stone and the straight edge at as many points as desired. This method is limited for testing sharpening stones over 1" wide because the edge of the stone might be flat thus preventing the feeler gauge from passing between the stone and the plate but the center of the stone could still be out of tolerance.

Method 4: CMM Machine

Items Needed:

- A CMM Machine

Measuring using a CMM (Coordinate Measuring Machines) A coordinate measuring machine measures the geometry of objects by sensing points on the surface of the object with a probe. Various types of probes are used in CMMs, including mechanical, optical, laser, and white light. The accuracy of these measurements are questionable due to the variations in the results produced by various CMM machines from different manufacturers. Also, this method is cost-prohibitive for testing the flatness of sharpening stones given that the cost of the machines range from $18,000 to $1,000,000 and hiring a service to perform the tests will typically cost $1000+ per test.

Summary:

The easiest, quickest and least expensive method for testing sharpening stones is the Machinist Straight Edge Method in Step 1 above. This method can test down to .001" which is sufficient for testing the flatness of sharpening stones for most applications.

We always welcome feedback about our articles. For feedback, suggestions or comments please Contact Us.

To read more articles click here Articles

References:

1. Precision Grinding, Inc. - Thickness, Parallelism and Flatness. How do they relate?