Types of Sharpening Stones

Topics Covered:

Which type of sharpening stone you choose is largely a matter of personal choice similar to what type of automobile you prefer. Some people love Arkansas stones and would use nothing else, others prefer diamonds stones for their speed and ease of maintenance and others would only sharpen with water stones. Most experiences sharpeners use a combination of two or three types.

Sharpening Stones are also known as whetstones. The word "whetstone" is derived from the word "whet" which means to sharpen. This is contrary to the common belief that the name comes from their need to be soaked prior to use.

There are four main types of sharpening stones.

1. Oil Stones

The oil stone has been used for many years to sharpen knives and tools. They are a man-made stone having abrasive particles bound together with a bonding agent. The name oil stone refers to the fact that you need oil to lubricate the stone before sharpening with it.

There are two common materials used make oil stones:

Aluminum Oxide - This is one of the most popular choices when it comes to man-made sharpening stone materials and a very effective abrasive for sharpening. Often orange or brown in color, aluminum oxide stones cut fast and are excellent for creating edges on knives. You'll find these stones labeled as coarse, medium or fine. Aluminum Oxide is a very hard abrasive rated at 9 on the Mohs Hardness Scale making it an excellent sharpening abrasive.

Silicon Carbide - This is the fastest cutting oil stone. Silicon Carbide stones usually come in a coarser grit so they can't produce an edge as sharp as the one from Aluminum Oxide or Novaculite.

Silicon Carbide stones have a Mohs Harness of 9-10 and are good for the initial course sharpening. Because they can sharpen quickly, you'll find most people starting their sharpening with them, then proceeding to an India stone before finishing up with an Arkansas.

Oil stones are inexpensive costing between $7 and $30 and have a typical grit range of 100-600.

2. Arkansas Stones

Arkansas Stones deserve their own classification because they can be used with oil or water. They are also called Novaculite. The word Novaculite comes from a Latin word meaning "razor stone". Arkansas stones have been quarried since the early 1800s from bedrock deposits found in the Ouachita Mountains of Arkansas. They are cut into rectangular shaped whetstones to be used for sharpening knives and tools.

The Arkansas stone is the most misunderstood of all sharpening abrasives. Much of the information found online is either flawed or completely inaccurate but that topic is best saved for its own article. The information given below is from our own experience and testing. The specific gravity ratings are from our own tests performed in May 2019. We tested four stones of each type. The values given below are an average of those four samples.

Arkansas stones come in four grades; Soft, Hard, Black and Translucent.

Soft Arkansas - The Soft Arkansas stone is the coarsest of the four. It is typically marbled in color with colors ranging from white, gray, black, orange or pink. The grit is equivalent to 400-600. The specific gravity of the Soft Arkansas stone is 2.22.

Hard Arkansas - The Hard Arkansas stone is the fine grit stone. It is typically white to off-white in color but can have some light orange or reddish colors mixed throughout the stone. The grit is equivalent to 800-1000. The specific gravity of the Hard Arkansas is 2.32.

Black Arkansas - The Black Arkansas stone is one of the finest of the four. It is an extra-fine stone and is black or blue-black in color. The Black Arkansas Stone has a grit equivalent to 2000 grit. The specific gravity of the Black Arkansas is 2.55.

Translucent Arkansas - The Translucent stone is also an extra-fine stone. The color may be a uniform shade of very light gray, white or they will sometimes have light shades of pink running through them. The grit is equivalent to 3500-4000. The specific gravity of the Translucent Arkansas is 2.56.

Water stones can be either natural or man-made (synthetic) stones. The term water stone is derived from the fact that water must be used to lubricate these stones. Natural Waterstones have been quarried in Belgium and Japan for centuries and hold a special place in sharpening stone history and lore.

Belgian whetstone production began as a result of the Roman Conquests and the stones have been exported from Belgium since the 17th century. There are two types of Belgian sharpening stones; the Coticule and the Belgian Blue Stone (BBW). The world famous Coticule is 8000 grit and the Belgian Blue Stone is 4000 grit.

Synthetic Water Stones

Synthetic water stones are man-made and popular with chefs and woodworkers. Synthetic water stones wear more quickly than other stones and must be lapped frequently to maintain flatness. They work faster than oil stones or Arkansas stones but slower than diamond stones.

Synthetic stones are available in a range of grits from 120 to 30,000 and cost from $30 to $160.

Diamond sharpening stones are the fastest growing type of sharpening stone and are quickly becoming the preferred stone for many chefs and professionals. Diamond stones are made of man-made diamonds electroplated onto a metal plate. The diamond particles are embedded into nickel plating which give them their exception durability.

They are extremely fast working, very durable and will quickly sharpen anything with a cutting edge including high carbon, stainless steel, and ceramic knives.

Diamond sharpening stones can be found with both a solid and interrupted surface. These stones remove steel quickly, require little maintenance and it is unlikely the average user will ever wear out a quality stone.

A word of caution, there are some very cheap diamond stone for sale that have the diamond mounted on a thin piece of steel roughly the thickness of a credit card. While some of these are of good quality, one should not expect them to be as durable or remain flat like a diamond stone that has the diamonds nickel plated onto a thicker, solid piece of solid steel.

A good quality diamond stone cost from $45 to $65 for a 3x8" stone.

Oil Stones:

Arkansas Stones:

Water Stones:

Diamond Stones:

To read more articles about sharpening click here Articles

We always welcome feedback about our articles. For feedback, suggestions or comments please Contact Us.

- Oil Stones

- Arkansas Stones

- Diamond Stones

- Water Stones

- Summary

Sharpening Stones are also known as whetstones. The word "whetstone" is derived from the word "whet" which means to sharpen. This is contrary to the common belief that the name comes from their need to be soaked prior to use.

There are four main types of sharpening stones.

1. Oil Stones

The oil stone has been used for many years to sharpen knives and tools. They are a man-made stone having abrasive particles bound together with a bonding agent. The name oil stone refers to the fact that you need oil to lubricate the stone before sharpening with it.

There are two common materials used make oil stones:

Aluminum Oxide - This is one of the most popular choices when it comes to man-made sharpening stone materials and a very effective abrasive for sharpening. Often orange or brown in color, aluminum oxide stones cut fast and are excellent for creating edges on knives. You'll find these stones labeled as coarse, medium or fine. Aluminum Oxide is a very hard abrasive rated at 9 on the Mohs Hardness Scale making it an excellent sharpening abrasive.

Silicon Carbide - This is the fastest cutting oil stone. Silicon Carbide stones usually come in a coarser grit so they can't produce an edge as sharp as the one from Aluminum Oxide or Novaculite.

Silicon Carbide stones have a Mohs Harness of 9-10 and are good for the initial course sharpening. Because they can sharpen quickly, you'll find most people starting their sharpening with them, then proceeding to an India stone before finishing up with an Arkansas.

Oil stones are inexpensive costing between $7 and $30 and have a typical grit range of 100-600.

2. Arkansas Stones

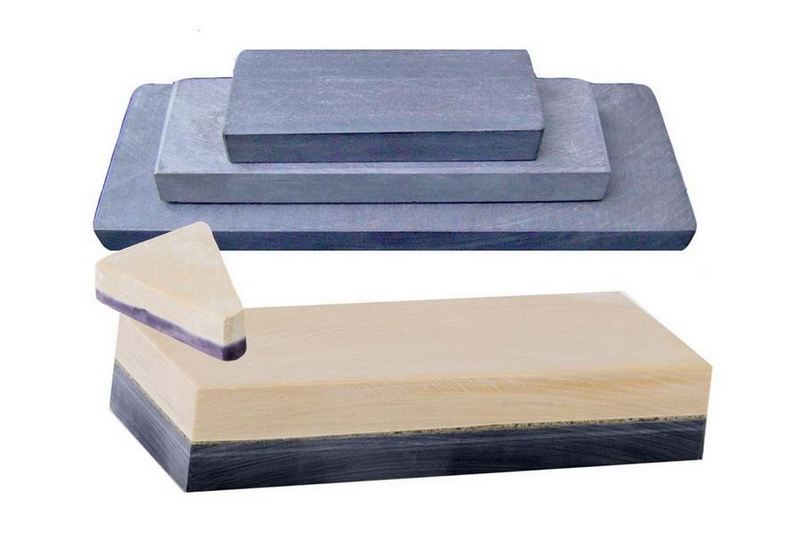

Arkansas Stones deserve their own classification because they can be used with oil or water. They are also called Novaculite. The word Novaculite comes from a Latin word meaning "razor stone". Arkansas stones have been quarried since the early 1800s from bedrock deposits found in the Ouachita Mountains of Arkansas. They are cut into rectangular shaped whetstones to be used for sharpening knives and tools.

The Arkansas stone is the most misunderstood of all sharpening abrasives. Much of the information found online is either flawed or completely inaccurate but that topic is best saved for its own article. The information given below is from our own experience and testing. The specific gravity ratings are from our own tests performed in May 2019. We tested four stones of each type. The values given below are an average of those four samples.

Arkansas stones come in four grades; Soft, Hard, Black and Translucent.

Soft Arkansas - The Soft Arkansas stone is the coarsest of the four. It is typically marbled in color with colors ranging from white, gray, black, orange or pink. The grit is equivalent to 400-600. The specific gravity of the Soft Arkansas stone is 2.22.

Hard Arkansas - The Hard Arkansas stone is the fine grit stone. It is typically white to off-white in color but can have some light orange or reddish colors mixed throughout the stone. The grit is equivalent to 800-1000. The specific gravity of the Hard Arkansas is 2.32.

Black Arkansas - The Black Arkansas stone is one of the finest of the four. It is an extra-fine stone and is black or blue-black in color. The Black Arkansas Stone has a grit equivalent to 2000 grit. The specific gravity of the Black Arkansas is 2.55.

Translucent Arkansas - The Translucent stone is also an extra-fine stone. The color may be a uniform shade of very light gray, white or they will sometimes have light shades of pink running through them. The grit is equivalent to 3500-4000. The specific gravity of the Translucent Arkansas is 2.56.

Arkansas Sharpening Stones

3. Water Stones

Water stones can be either natural or man-made (synthetic) stones. The term water stone is derived from the fact that water must be used to lubricate these stones. Natural Waterstones have been quarried in Belgium and Japan for centuries and hold a special place in sharpening stone history and lore.

Belgian whetstone production began as a result of the Roman Conquests and the stones have been exported from Belgium since the 17th century. There are two types of Belgian sharpening stones; the Coticule and the Belgian Blue Stone (BBW). The world famous Coticule is 8000 grit and the Belgian Blue Stone is 4000 grit.

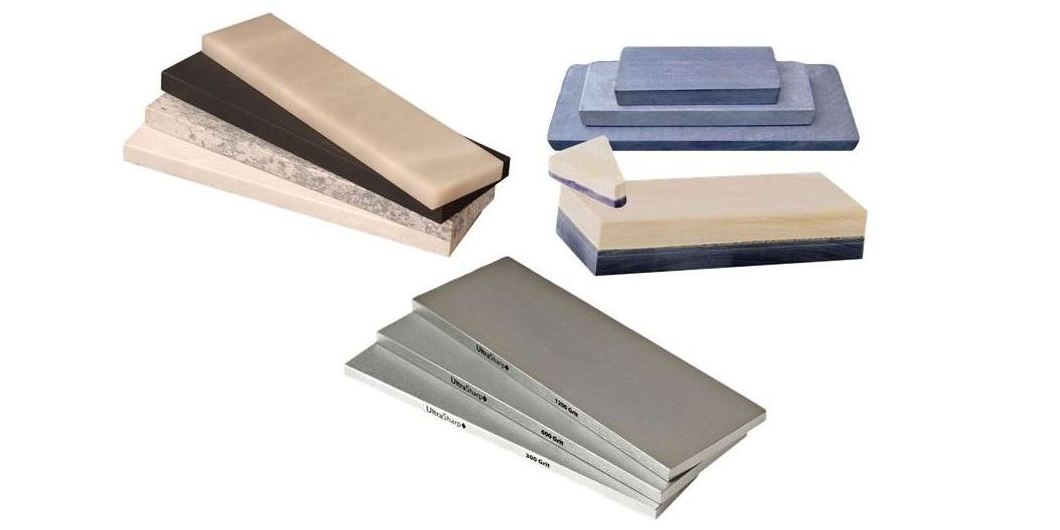

Belgian Sharpening Stones

Natural Japanese sharpening stones are becoming scarce after centuries of quarrying but they are still available today. Most of these stones are mined near Kyoto, Japan and are highly sought after by straight razor users and knife enthusiasts. Japanese whetstones range in grits from 500 to 10,000 and cost from $25 for a Nagura stone to $500+ for larger stones.

Synthetic Water Stones

Synthetic water stones are man-made and popular with chefs and woodworkers. Synthetic water stones wear more quickly than other stones and must be lapped frequently to maintain flatness. They work faster than oil stones or Arkansas stones but slower than diamond stones.

Synthetic stones are available in a range of grits from 120 to 30,000 and cost from $30 to $160.

Synthetic Water Stones by Norton

4. Diamond Sharpening Stones

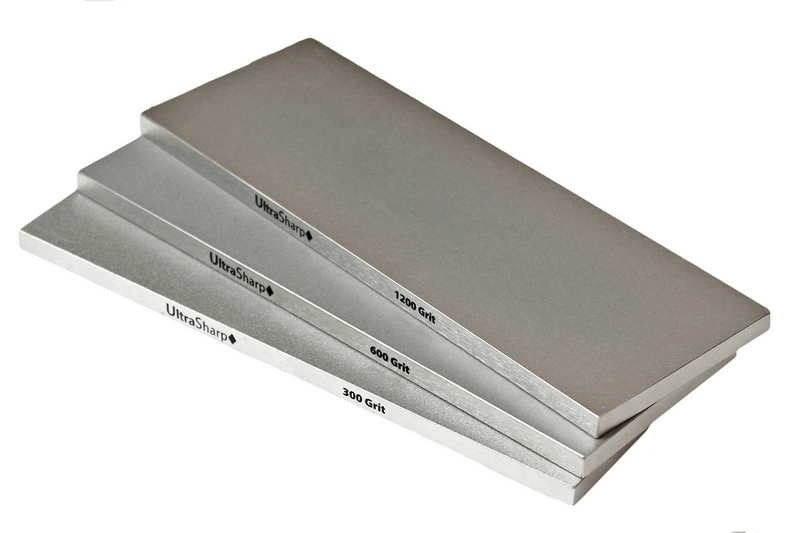

Diamond sharpening stones are the fastest growing type of sharpening stone and are quickly becoming the preferred stone for many chefs and professionals. Diamond stones are made of man-made diamonds electroplated onto a metal plate. The diamond particles are embedded into nickel plating which give them their exception durability.

They are extremely fast working, very durable and will quickly sharpen anything with a cutting edge including high carbon, stainless steel, and ceramic knives.

Diamond sharpening stones can be found with both a solid and interrupted surface. These stones remove steel quickly, require little maintenance and it is unlikely the average user will ever wear out a quality stone.

A word of caution, there are some very cheap diamond stone for sale that have the diamond mounted on a thin piece of steel roughly the thickness of a credit card. While some of these are of good quality, one should not expect them to be as durable or remain flat like a diamond stone that has the diamonds nickel plated onto a thicker, solid piece of solid steel.

A good quality diamond stone cost from $45 to $65 for a 3x8" stone.

Diamond Sharpening Stones

Summary:Oil Stones:

- Man-made stones

- Use with oil

- Materials: Aluminum Oxide or Silicone Carbide

- Grit range: 100-400

- Costs: $7 - $30

- Common Size: 2"x6" or 2"x8"

- Popular Brands: Norton, Pride Abrasives

- Natural stones quarried in Arkansas, USA

- Use with oil or water

- Materials: Novaculite

- Grit range: 400-4000

- Costs: $20 - $200

- Common Size: 2"x6", 2"x8", 3"x8", 3"x10"

- Natural and man-made stones

- Use with water

- Materials: ceramic

- Grit range: 120-30,000

- Costs: $20 - $500

- Common Size: 3"x8"

- Popular Brands: Shapton, Pride Abrasive, Norton

- Harder than all other abrasives

- Use with lubricant (water, glass cleaner, Krud Kutter)

- Materials: micronized monocrystalline diamonds

- Grit range: 120-8000

- Costs: $20 - $100

- Common Size: 2"x6", 3"x8", 4"x10"

- Popular Brands: DMT, Ultra Sharp

We always welcome feedback about our articles. For feedback, suggestions or comments please Contact Us.