What is an Arkansas Stone?

Topics Covered:

Arkansas Stones are a natural sharpening stone mined only in the Ouachita Mountains of Arkansas. They are quarried by blasting and the use of diamond saws. They are then cut into rectangular shaped whetstones to be used for sharpening knives and tools. - Definition of Arkansas Stones

- Types of Arkansas Stones

- Grits and Density

- Which lubricant to use

- Summary and References

Arkansas Stones are also called Arkansas Sharpening Stones or Arkansas Whetstones.

Arkansas stones are made of Novaculite. The word Novaculite[1] comes from a Latin word meaning "razor stone".

Novaculite is a rock that is made of quartz crystals. Quartz is a mineral made of the compound Silicon Dioxide. There can be other impurities in the quartz, but the quartz crystals must contain 99% Silicon Dioxide to be used for sharpening stones.

Quartz is hexagonal in shape and has sharp edges which gives Arkansas Stones their unique sharpening ability. It has a Mohs hardness of 7 which is much harder than any steel used for making knives. [2] [3] [4]

Arkansas stones are made of Novaculite. The word

Novaculite is a rock that is made of quartz crystals. Quartz is a mineral made of the compound Silicon Dioxide. There can be other impurities in the quartz, but the quartz crystals must contain 99% Silicon Dioxide to be used for sharpening stones.

Quartz is hexagonal in shape and has sharp edges which gives Arkansas Stones their unique sharpening ability. It has a Mohs hardness of 7 which is much harder than any steel used for making knives. [2] [3] [4]

Quartz Crystal Cluster

Novaculite that is used to make sharpening stones is actually called "Arkansas Novaculite". The term Arkansas Novaculite was first used in 1892 when geologist L.S. Griswold published a report entitled, Whetstones and the Novaculites of Arkansas. He documented these rocks and called them the Arkansas Novaculite.[5][8] This is the form of Novaculite used today for making Arkansas Sharpening Stones. Not all novaculite is of a high enough quality to be used for sharpening stones. The lesser quality Novaculite is used as concrete aggregate, road construction material and other industrial applications.

The highest quality material that is used to make Arkansas stones can only be found in Garland and Hot Spring Counties in Arkansas. These particular forms of novaculite are chosen to make sharpening stones because of their porosity, uniform grain size, and the sharp edges of the microcrystalline quartz that make up the rock.

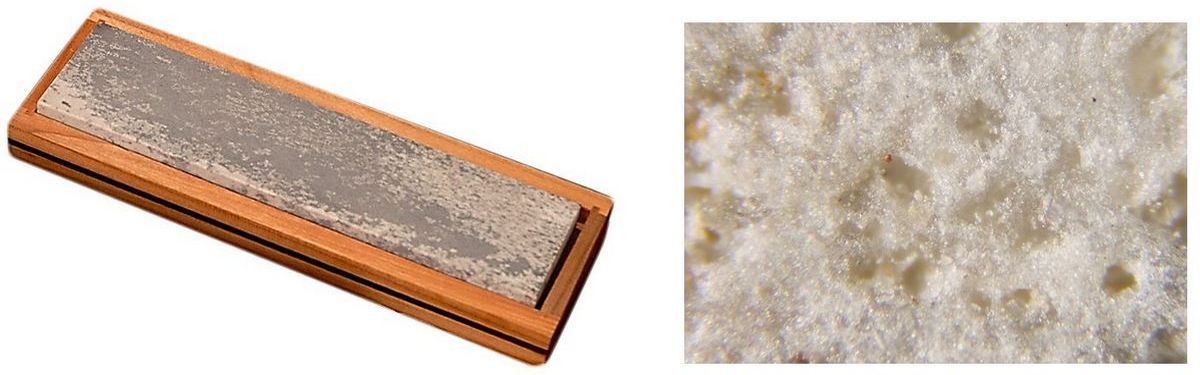

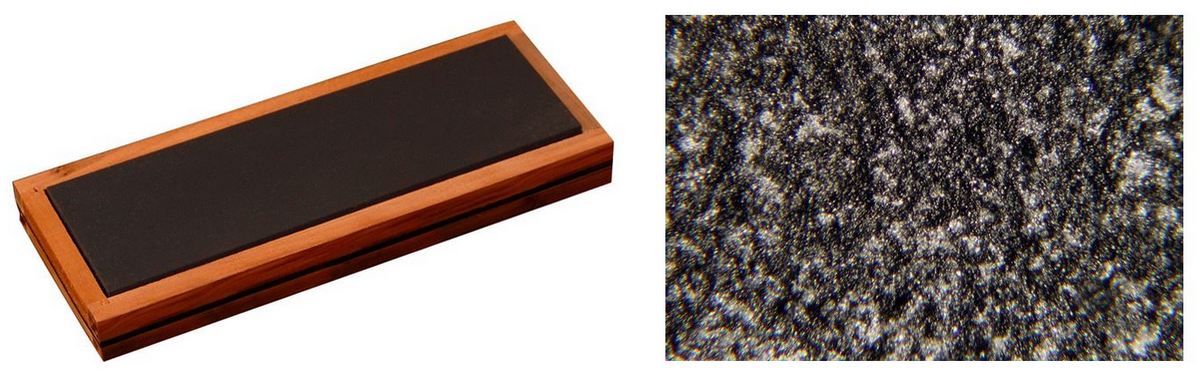

The porosity is due to cavities that were formed when carbonate minerals leached out during weathering. This variation in porosity is reflected in a difference in luster in the stones. The more porous Soft and Hard Arkansas Stones have the appearance of unglazed porcelain while the denser Black and Translucent Arkansas Stones have a slight, waxy luster.

There is a myth that the supply of Arkansas stones is diminishing and some grades are "extinct". This is false. The amount of novaculite that exists in the Ouachita Mountains will allow for the continued production of Arkansas sharpening stones for the indefinite future.

History

Novaculite was used by people living in the Ouachita Mountains at least as far back as the Archaic Period between 9500 and 650 BC. It can be found everywhere in the region. Local people sourced it from rock outcroppings or riverbeds and made weapons and tools like arrowheads, spearheads, knives and axes.

Native American tribes also mined Novaculite and used it for trade over much of North America. Many aboriginal Novaculite quarries have been documented and some of these historically significant sites still exist today.

The first European settlers in Arkansas were French trappers[6] who used Arkansas stones to sharpen their knives and tools. They needed very sharp knives to prepare their animal hides for trading. Their axes and saws were used to cut timber and clear land for agriculture.

Arkansas stones have been quarried since the early 1800s. Quarrying novaculite for whetstones became an important industry in the region during the nineteenth century. Arkansas sharpening stones are marketed worldwide with large quantities being exported to Germany and Japan.

Arkansas Sharpening Stone Types, Color and Grit

Arkansas stones come in four grades; Soft, Hard, Black and Translucent.

All grades of Arkansas Stones are composed mostly of 1-5 micron quartz grains.[1] They contain traces of other elements such as aluminum, iron, manganese, titanium, calcium, magnesium, sodium, and potassium.

Arkansas Stone ColorsAll grades of Arkansas Stones are composed mostly of 1-5 micron quartz grains.[1] They contain traces of other elements such as aluminum, iron, manganese, titanium, calcium, magnesium, sodium, and potassium.

Arkansas stones have a variety of colors including white, off-white, gray, brown, black, blue-black, pink, red, orange and occasionally purple. All novaculite is translucent; the color variation comes from the trace minerals dispersed throughout the rock. Many of the same colors exist in more than one grade of stone. Color does not distinguish between grits of Arkansas stones.

Soft Arkansas - The Soft Arkansas Stone is the coarsest of the four types of Arkansas Stones. It is typically marbled in color with colors ranging from white, gray, black, orange or pink.

Hard Arkansas - The Hard Arkansas Stone is the fine grit stone. It is typically white to off-white in color but can have some light orange or reddish colors mixed throughout the stone.

Black Arkansas - The Black Arkansas Stone is an extra-fine grit. It is black, blue-black or dark grey in color.

Translucent Arkansas - The Translucent Arkansas Stone is also an extra-fine stone. The color may be a uniform shade of very light gray, white or they will sometimes have light shades of orange or pink. How are Arkansas Stones Graded?

Arkansas stones are graded according to the specific gravity or the density of each stone. However, specific gravity only compares the hardness of the stones. It doesn't tell us anything about the actual grit.

What Grit is an Arkansas Stone?

We learned color doesn't distinguish Arkansas stone grits and we know specific gravity doesn't determine the grit either. So how do we know what grit Arkansas Stones are?

The best method for determining grit is evaluating scratch patterns. Using scratch patterns is a common industry practice for evaluating the effective grit of abrasive materials.

The grit ratings below are from a microscopic evaluation of Arkansas stones done in 2019.

You can see the full article here - Arkansas Sharpening Stone Grits

The specific gravity ratings are from our own tests performed in May 2019. We tested four stones of each type. The values given below are an average of those four samples.

Soft Arkansas Stone Grit - 1200 | Specific Gravity 2.22 | 12 micron | .00047" The best method for determining grit is evaluating scratch patterns. Using scratch patterns is a common industry practice for evaluating the effective grit of abrasive materials.

The grit ratings below are from a microscopic evaluation of Arkansas stones done in 2019.

You can see the full article here - Arkansas Sharpening Stone Grits

The specific gravity ratings are from our own tests performed in May 2019. We tested four stones of each type. The values given below are an average of those four samples.

Hard Arkansas Stone Grit - 1500 | Specific Gravity 2.36 | 10-11 micron | .00041"

Black Arkansas Stone Grit - 2300-2500 | Specific Gravity 2.55 | 7-7.5 micron | .00028"

Translucent Arkansas Grit - 3500-4000 | Specific Gravity 2.53 | 5.5-6 micron | .00023"

What is the Best Lubricant to use for Arkansas Stones?

You can use either water or oil with Arkansas sharpening stones. It is really a matter of personal choice.

A lubricant suspends the steel shavings from your blade and prevents them from clogging the pores of your stone. Water is thinner than oil. It will sink in to the cavities of the stones more quickly so you will have to add it more frequently (similar to using a water stone).

Our testing has shown that a light mineral oil is the best lubricant to use on Arkansas sharpening stones. It does a better job of preventing the stones from clogging. If you are sharpening in a kitchen and have a sink nearby, then using water to lubricate Arkansas is a viable method.

Regardless of the lubricant you choose, Arkansas stones should be cleaned after each use by putting lubricant on the stone, rubbing it around and then wiping the excess lubricant away with a clean cloth. If you're sharpening with oil then use whatever oil you are using as a lubricant. If you're using water then soapy water should be used to clean the stone.

Summary: A lubricant suspends the steel shavings from your blade and prevents them from clogging the pores of your stone. Water is thinner than oil. It will sink in to the cavities of the stones more quickly so you will have to add it more frequently (similar to using a water stone).

Our testing has shown that a light mineral oil is the best lubricant to use on Arkansas sharpening stones. It does a better job of preventing the stones from clogging. If you are sharpening in a kitchen and have a sink nearby, then using water to lubricate Arkansas is a viable method.

Regardless of the lubricant you choose, Arkansas stones should be cleaned after each use by putting lubricant on the stone, rubbing it around and then wiping the excess lubricant away with a clean cloth. If you're sharpening with oil then use whatever oil you are using as a lubricant. If you're using water then soapy water should be used to clean the stone.

Arkansas Stones are a natural sharpening stone mined only in the Ouachita Mountains of Arkansas.

The four grades of Arkansas Stones are Soft, Hard, Black and Translucent.

Arkansas stones are made of Novaculite. Novaculite is a rock that is made of quartz crystals.

Quartz is hexagonal in shape and has sharp edges which give Arkansas stones their unique sharpening ability.

Arkansas Stones are composed mostly of 1-5 micron quartz grains. They contain traces of other elements such as aluminum, iron, manganese, titanium, calcium, magnesium, sodium, and potassium. Some of these elements contribute to their color.

Color doesn't distinguish between grits of Arkansas stones. Specific gravity testing measures the density of the stone but does not provide an actual grit. The best method for determining grit is evaluating scratch patterns.

Arkansas Stones can be used with either oil or water but a mineral oil is the best choice in most circumstances.

For our full article on Arkansas Stone grits please click here - Arkansas Sharpening Stone Grits

To see Arkansas Stone Frequently Asked Questions please click here - Arkansas Stones FAQ

To read more articles about sharpening click here - Sharpening Articles

We always welcome feedback about our articles. For feedback, suggestions or comments please Contact Us.

References: The four grades of Arkansas Stones are Soft, Hard, Black and Translucent.

Arkansas stones are made of Novaculite. Novaculite is a rock that is made of quartz crystals.

Quartz is hexagonal in shape and has sharp edges which give Arkansas stones their unique sharpening ability.

Arkansas Stones are composed mostly of 1-5 micron quartz grains. They contain traces of other elements such as aluminum, iron, manganese, titanium, calcium, magnesium, sodium, and potassium. Some of these elements contribute to their color.

Color doesn't distinguish between grits of Arkansas stones. Specific gravity testing measures the density of the stone but does not provide an actual grit. The best method for determining grit is evaluating scratch patterns.

Arkansas Stones can be used with either oil or water but a mineral oil is the best choice in most circumstances.

For our full article on Arkansas Stone grits please click here - Arkansas Sharpening Stone Grits

To see Arkansas Stone Frequently Asked Questions please click here - Arkansas Stones FAQ

To read more articles about sharpening click here - Sharpening Articles

We always welcome feedback about our articles. For feedback, suggestions or comments please Contact Us.

1. Arkansas Geological Survey (formerly Arkansas Geological Commission) - Novaculite (Silica Stone)

2. Engineering Fundamentals - Mohs (HM) to Rockwell (HRA Converter

3. A.G. Russell Steel Chart

4. A.G. Russell Non-Stainless Steel Chart

5. Holbrook, D. F., and Stone C. G., 1978, Arkansas Novaculite -A silica resource, in Johnson, K. S. and Russell, J. A., eds., Thirteenth Annual Forum on the Geology of Industrial Minerals: Oklahoma Geological Survey Circular 79, p. 51-58.

6. H. Pennington, Encyclopedia of Arkansas. Novaculite

7. Arkansas Archeological Survey - Arkansas Archeological Survey 2016, Arkansas Novaculite: A Virtual Comparative Collection.

8. Griswold, L. S., 1892, Whetstones and the novaculites of Arkansas: Arkansas Geological Survey Annual Report for 1890, v. III, 443 p.

2. Engineering Fundamentals - Mohs (HM) to Rockwell (HRA Converter

3. A.G. Russell Steel Chart

4. A.G. Russell Non-Stainless Steel Chart

5. Holbrook, D. F., and Stone C. G., 1978, Arkansas Novaculite -A silica resource, in Johnson, K. S. and Russell, J. A., eds., Thirteenth Annual Forum on the Geology of Industrial Minerals: Oklahoma Geological Survey Circular 79, p. 51-58.

6. H. Pennington, Encyclopedia of Arkansas. Novaculite

7. Arkansas Archeological Survey - Arkansas Archeological Survey 2016, Arkansas Novaculite: A Virtual Comparative Collection.

8. Griswold, L. S., 1892, Whetstones and the novaculites of Arkansas: Arkansas Geological Survey Annual Report for 1890, v. III, 443 p.